Purpose-Built AI Driven by Experience Proven to Scale

Think AI is the same for every industry? We don’t think so. Finally, there’s AI for the Modern Equipment Operator.

We improve the outcomes of process industries with the unmistakable power of AI. With 200+ years of combined industry experience, we understand your needs firsthand. Hence, we created the world’s first AI Expert by combining cutting edge research and decades of domain knowledge to keep you ten steps ahead of process inefficiencies and equipment failures across the full plant.

Real-Time Predictions. Long-term Benefits

Increase Availability

Increase Productivity

Reduce Maintenance

Increase Efficiency

Purpose-Built AI

Driven by Experience

Proven to Scale

Think AI is the same for every industry? We don’t think so. Finally, there’s AI for the Modern Equipment Operator.

We improve the outcomes of process industries with the unmistakable power of AI. With 200+ years of combined industry experience, we understand your needs firsthand. Hence, we created the world’s first AI Expert by combining cutting edge research and decades of domain knowledge to keep you ten steps ahead of process inefficiencies or equipment failures across the full plant.

Real-Time Predictions. Long-term Benefits

Increase Availability

Increase Productivity

Reduce Maintenance

Increase Efficiency

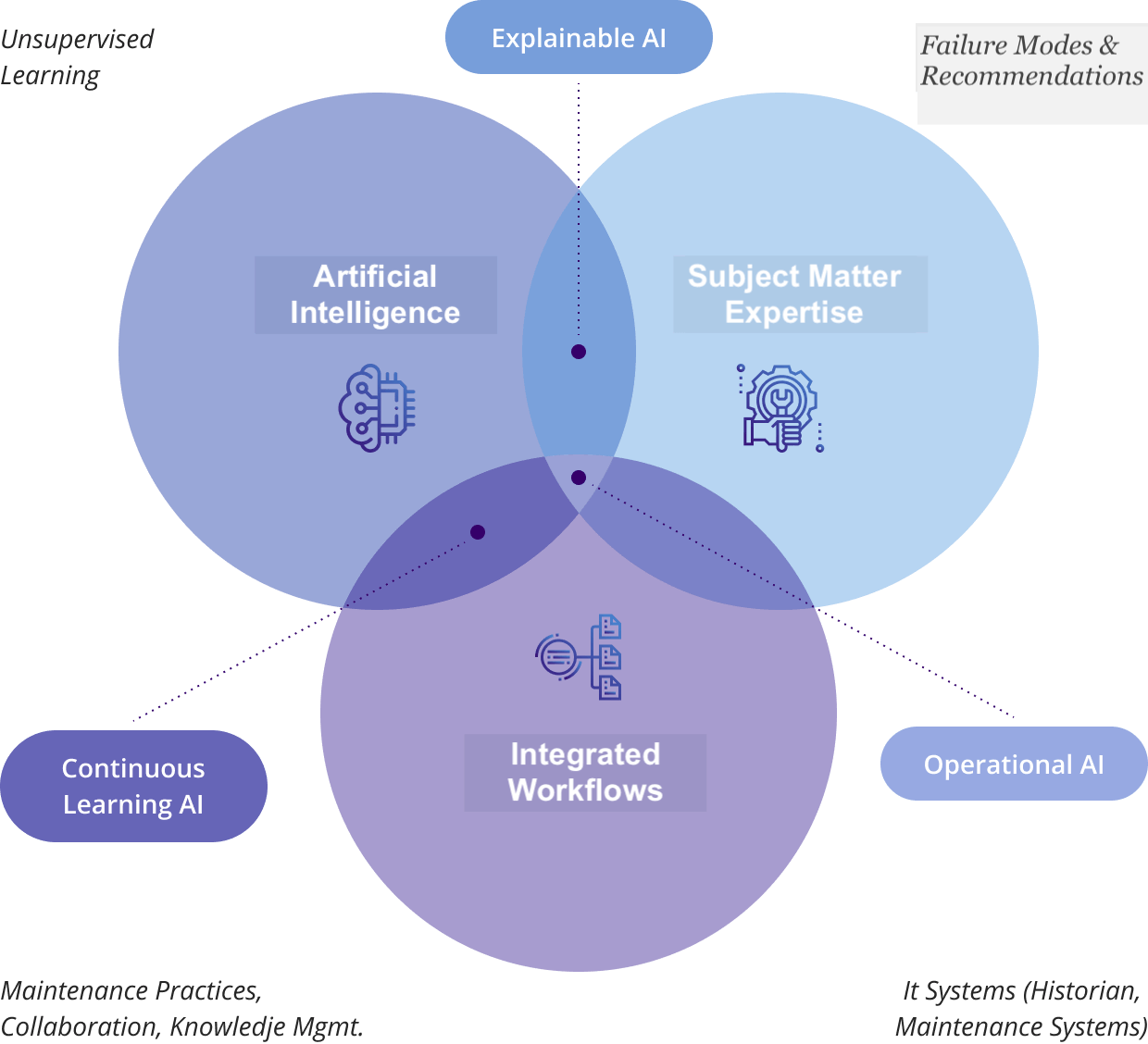

UptimeAI Starts Delivering in 4 Simple Steps

Connect

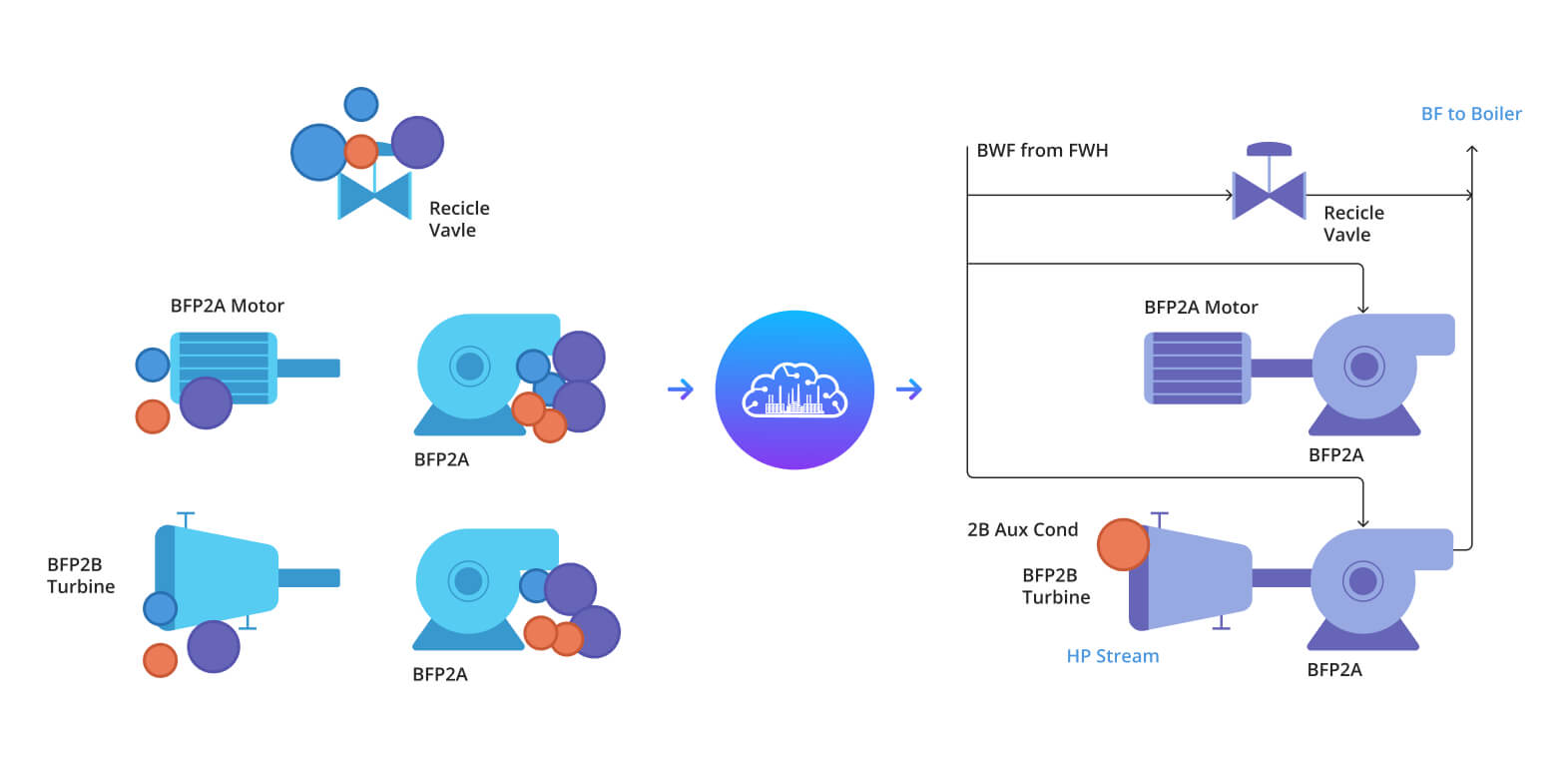

Integrates with DCS, CMMS, historians, and IoT platforms.

Diagnose

AI correlates sensor data, maintenance logs, and process variables to pinpoint root causes.

Prescribe

Delivers step-by-step actions to remediate the problem.

Learn

Improves accuracy by incorporating engineer feedback into AI models.

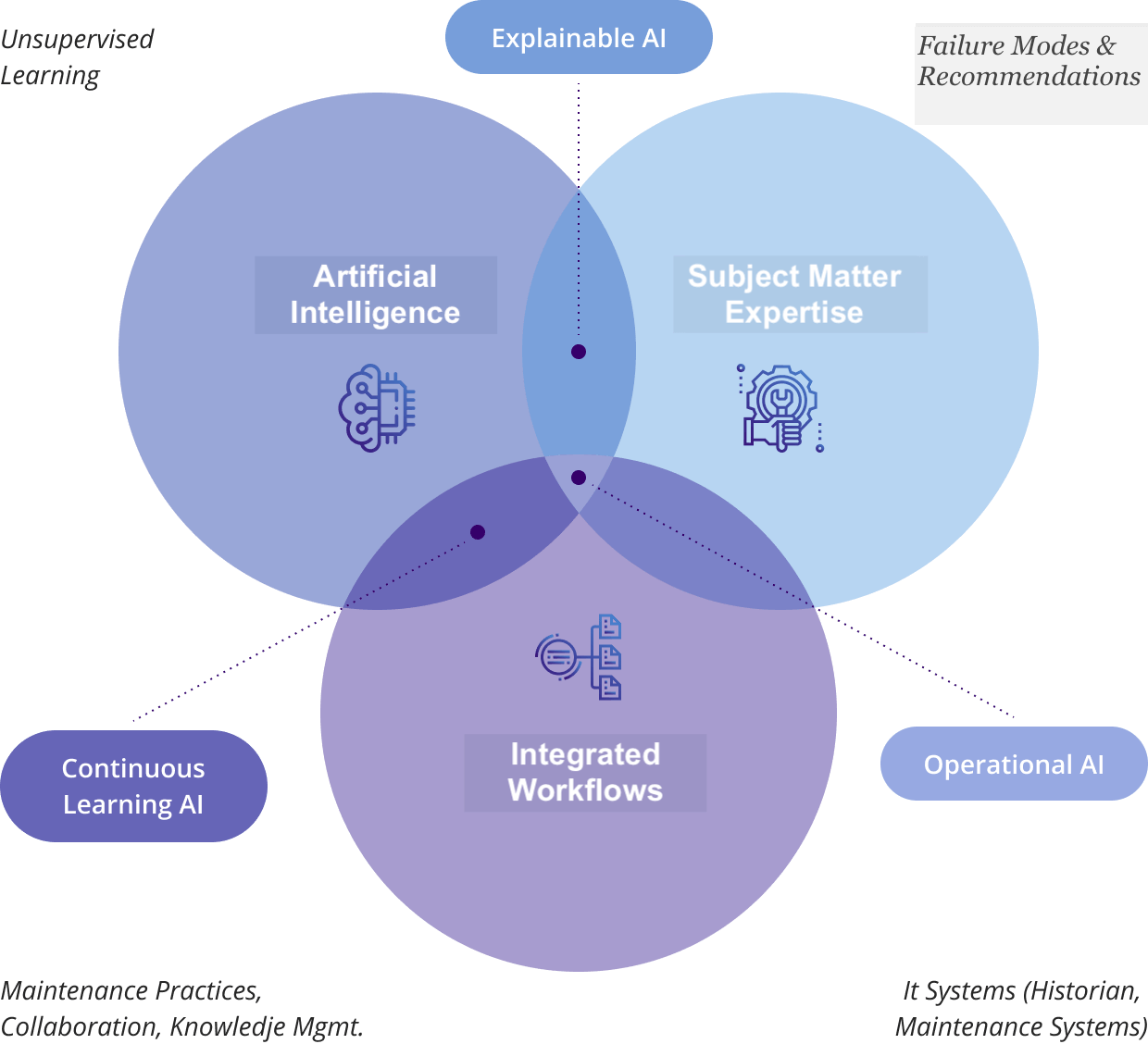

AI Expert Way To Predict and Fix Issues

Accurate Alerts Vs 1000s of Noise Alerts

UptimeAI uses a unique system approach powered by deep learning to understand the correlations between upstream and downstream operations to reduce the flood of alarm spam to a precise alarms that show the underlying cause.

UptimeAI lets engineers focus on what matters most – understand reasons behind symptoms and make operational decisions rather than sorting alarms.

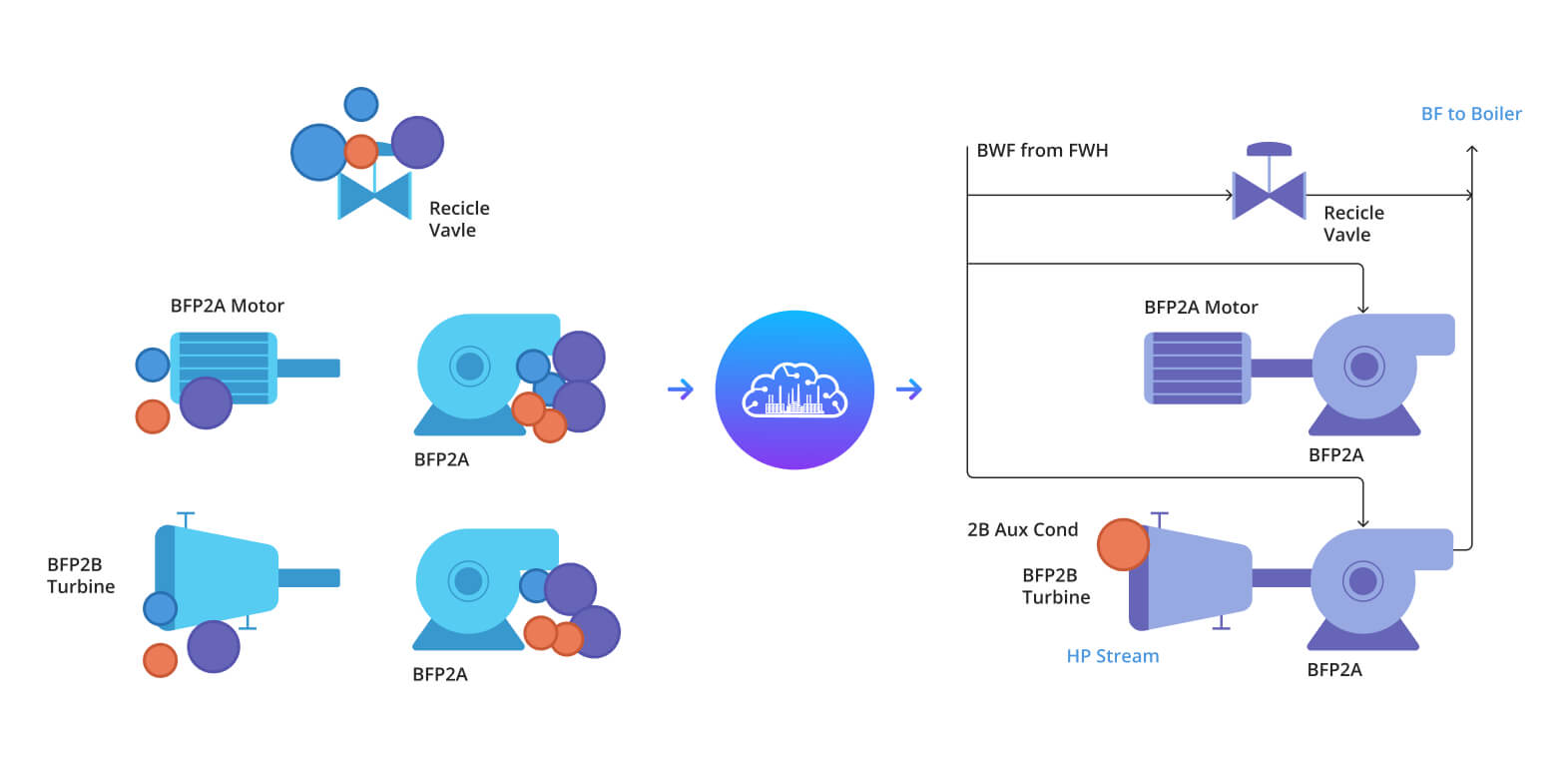

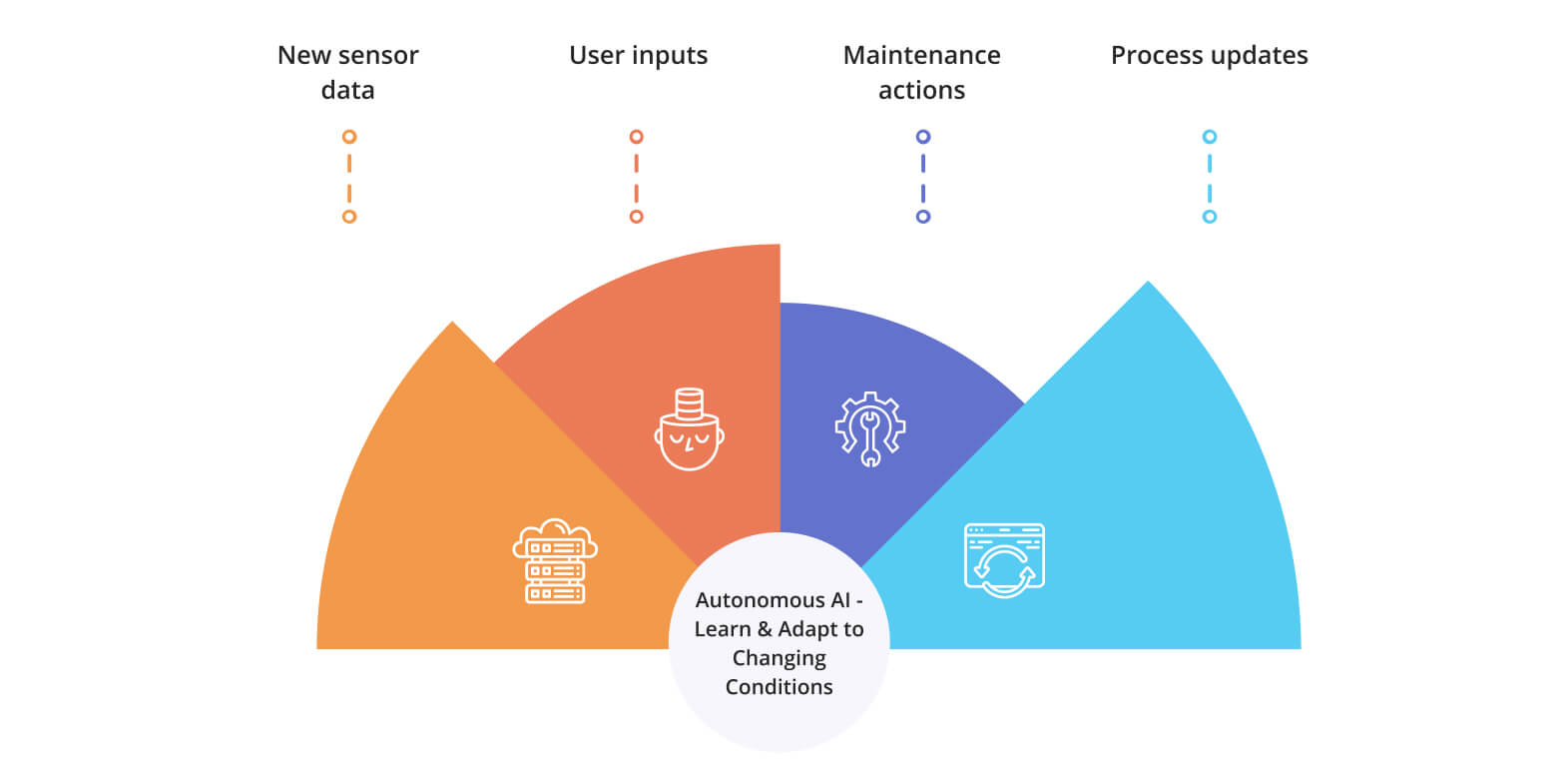

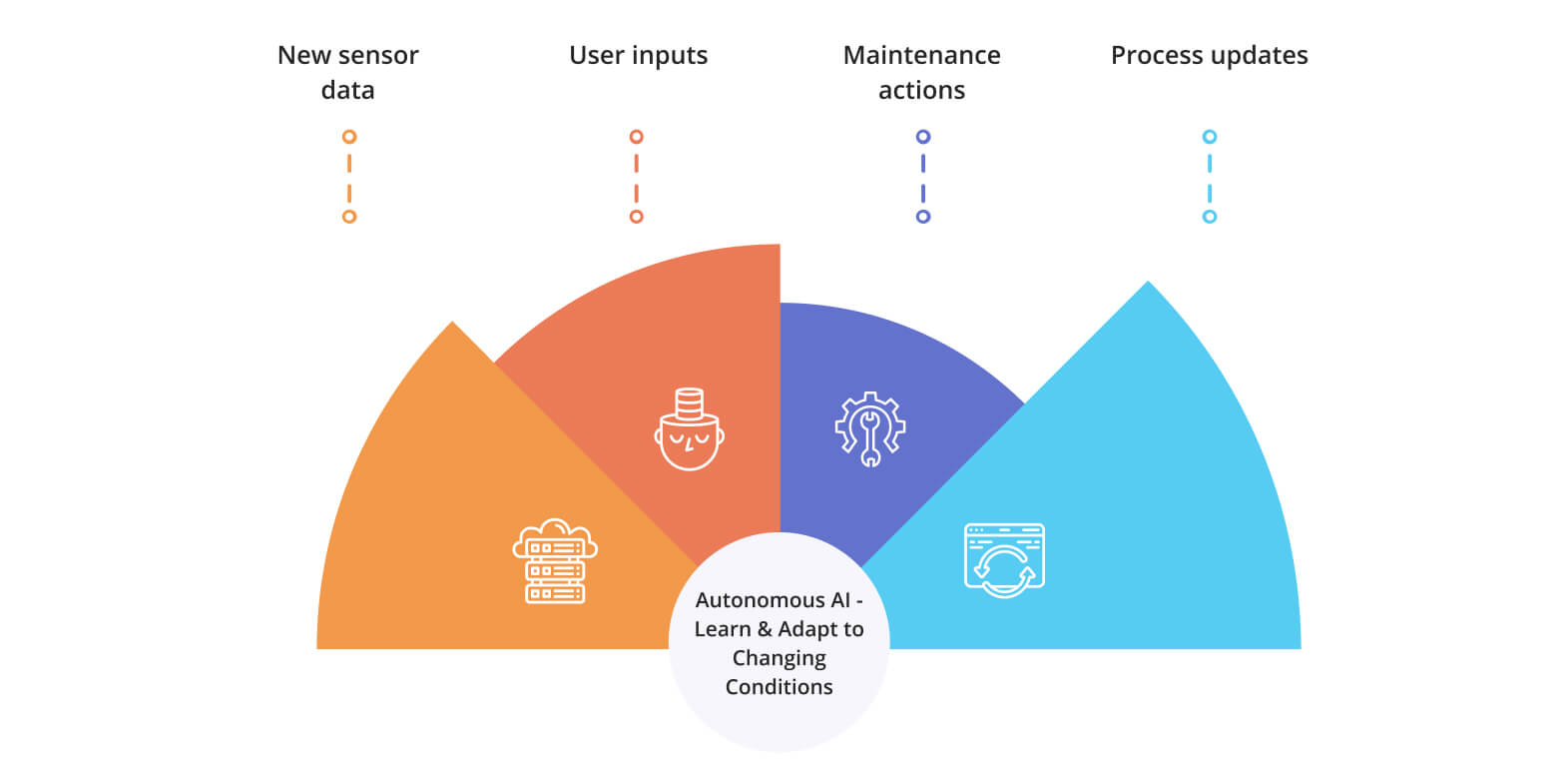

Zero Manual Rules with Continuous Learning

Plants operations are dynamic – bad sensors, changing process, maintenance, and others. UptimeAI’s autonomous AI engine continuous learns from new sensor data and user activities to automatically adjust the models and learn best practices with user permission.

No more manual updating of rules and models – always be up to date with the power of AI.

Hours Vs weeks to resolve issues

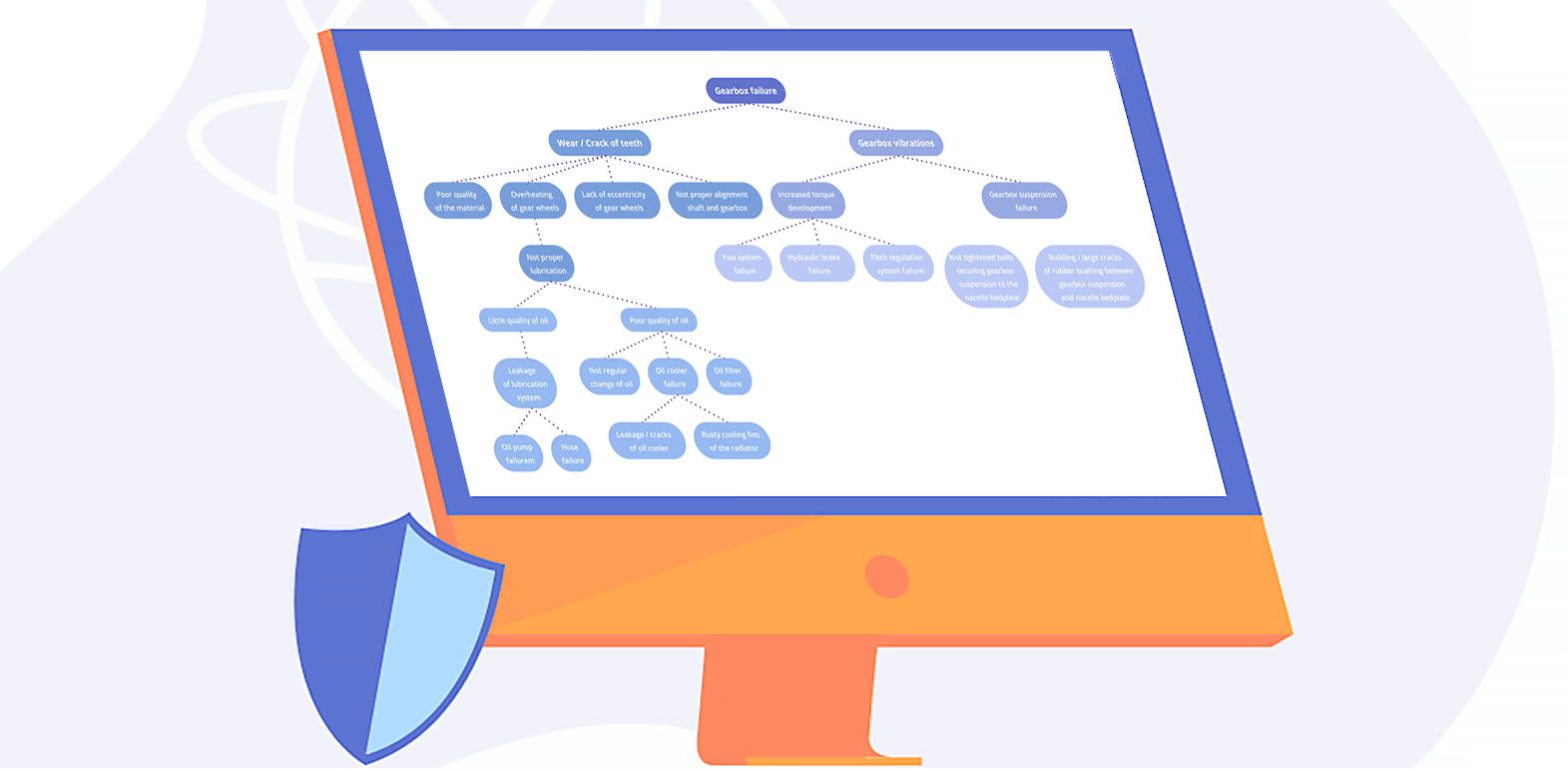

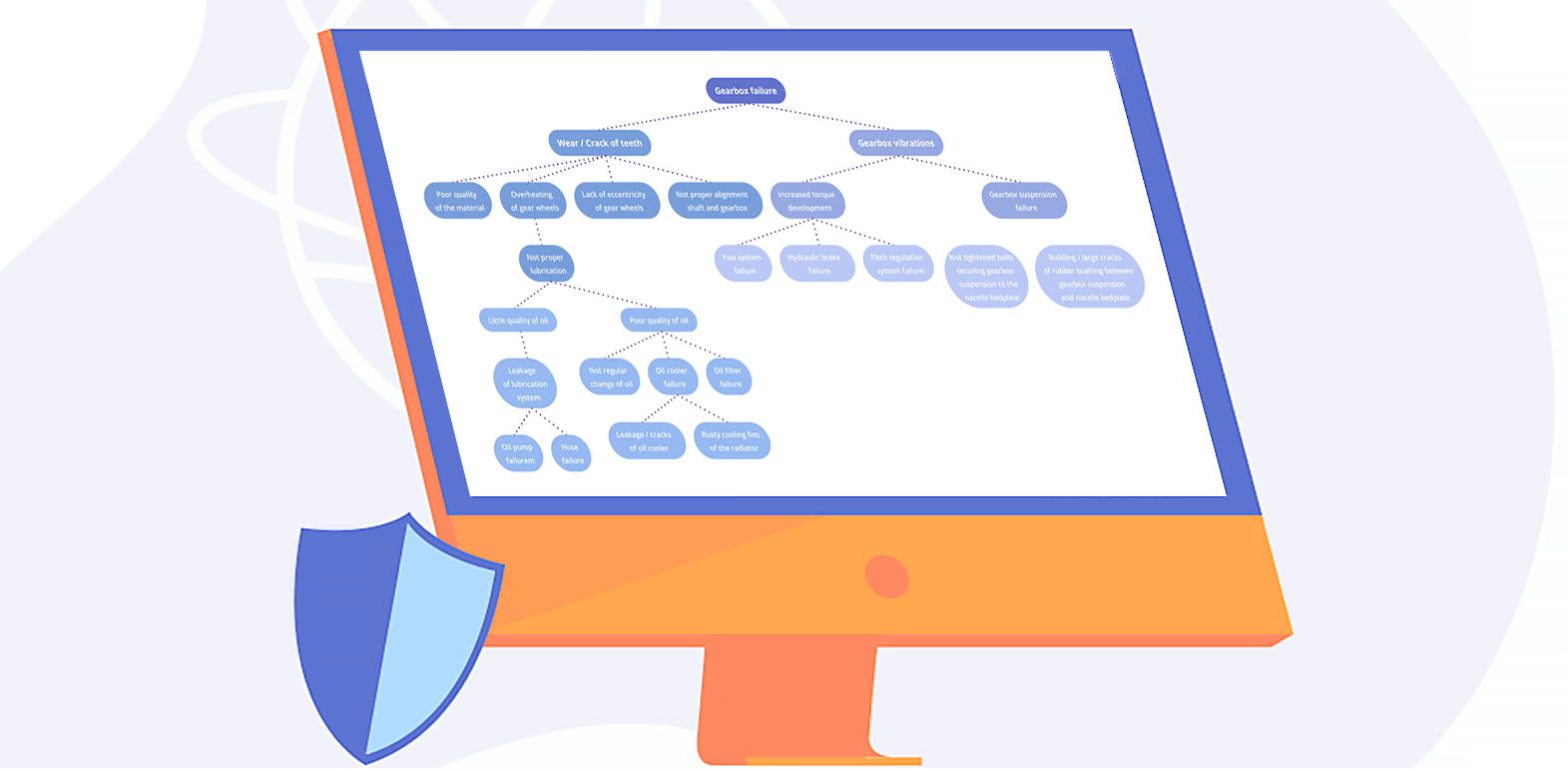

UptimeAI automates and explains fault diagnosis and recommends actions because we understand the relationships and dependencies between symptoms, failure modes, and fixes. The UptimeAI inferencing engine has built-in database for over 120+ equipment types with 500+ failure modes to provide precise answers.

Focus on fixing problems, not finding them.

Pin - pointed alerts Vs 1000s of noise alerts

UptimeAI uses a unique system approach powered by deep learning to understand the correlations between upstream and downstream operations to reduce the flood of alarm spam to a single precise alarm. UptimeAI lets engineers focus on what matters most – making operational decisions rather than sorting alarms.

Zero Manual Rules with Dynamic Continuous Learning

Plants operations are dynamic – bad sensors, changing process, maintenance, etc. UptimeAI’s autonomous AI engine continuous learns from new sensor data and user activities to automatically adjust the models and learn best practices with user permission. No more updating manual rules and models – always be up to date with the power of AI.

Hours Vs weeks to resolve issues

UptimeAI automates and explains fault diagnosis and recommends actions because we understand the relationships and dependencies between symptoms, failure modes, and fixes. The UptimeAI inferencing engine has built-in database for over 120+ equipment types with 500+ failure modes to provide precise answers. Focus on fixing prob lems, not finding them

Proven to Perform

With UptimeAI, you are one step ahead of unexpected losses. Traditional approaches cannot keep up with the complexity of large data and process. With UptimeAI, we can get early warnings and accurate diagnosis on equipment/process anomalies and loss of efficiency, increasing plant profitability.

UptimeAI Advantage

Cover Full Balance of Plant

Pattern Recognition Software & Generic AI Platforms Can't Cover Full Plant

UptimeAI has been designed from ground up to scale to the entire plant – every asset, every sensor. 120+ equipment fingerprints based on 200+ years of subject matter experience means rapid deployment with high quality insights. Further, the unique system approach using deep learning combines multiple assets and types of equipment to reduce number of models by 10x and draw deep insights based on inter-equipment and equipment-process correlations.

More Coverage, Faster Returns, Higher Quality Insights Even With Fewer Sensors.

- High Accuracy

- Explains complex issues

- Separate data quality module

- Grouped alerts

- Automated model updates

- Advanced analysis

- Detect equipment failures

- Detect process degradation

- Built-in fault diagnosis

- Prescriptive recommendations

- Collaboration / Knowledge mgmt.

- Integrated maintenance info

Trusted by Plant Heads in world’s leading Heavy Manufacturing Industies

What our Champions say about us?

What Analysts Say

“UptimeAI is unique because it focuses on helping customers solve issues relating to heavy asset and process operations by automating and explaining fault diagnosis and providing recommended actions.”

Sankara Narayan

Industry Director, Frost & SullivanWhat Customer Say

“UptimeAI fits the bill, with its rapid deployment and prescriptive suggestions designed for clear communication with our operations teams.”

E.R. Raj Narayanan

Chief Manufacturing Officer andBusiness Head of UltraTech Cement

Generate ROI in Just 6-12 weeks

Let’s start a conversation. UptimeAI is ready to deploy out of the box, and our expert team is here to support you every step of the way.